Food Grade Water Pump

Home > Food Grade Water Pump

Food grade water pump refers to a 24v or 12v liquid transfer pump that made by food grade material, we can also call them food safe water pump. It is a type of mini water pump whose components that direct contact with working liquid such as food, beverages, drinking water, are made by food grade materials. Its materials must meet certain food safety requirements to ensure that they are not harmful to consumer health. Food grade water pump is suitable for transferring food, beverages, and drinking water for coffer maker, water dispenser, beverage machine, brewing equipment, etc. It is an indispensable conveying equipment for food, chemical, pharmaceutical and other industries.

Nowadays, people pay more and more attention to food safety, with the improvement of people’s living standards. That, makes food safe pumps are widely used in kitchen beverage appliances, as well as food, medicine and other manufacturing industries.

Standard Food Grade Water Pumps Series by VOVYO:

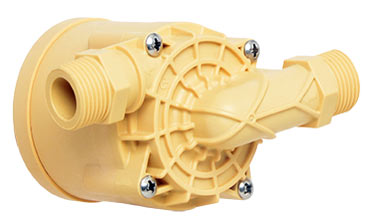

Food Safe Water Pump VP25A

Food Safe water pump VP25A is a high quality made dc water pump. It is used in home appliance such as coffer maker,juice machine,personal care products,etc.

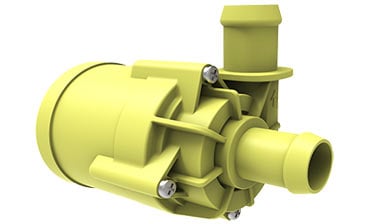

Food Grade Transfer Pump VP30C

This Food Grade Transfer Pump is a small Battery powered water pump which driven by a BLDC motor.It is widely used in coffer maker, dispenser, tea maker, etc.

Food Grade Water Pump VP35C

Food Grade Water Pump VP35C is a food safe water pump. It can be driven by dc power supply, battery, solar panel, etc. Well sold in Asia, India,US,and EU market.

Food Safe Pump VP40K

Food safe pump VP40K is a small electric water pump built by a brushless dc motor. Mainly used for home appliance such as coffee maker, juice machine, etc.

Food Grade Pumps For Brewing VP60B

Food Grade Pumps For Brewing VP60B is a miniature water pump which made by food grade material. People usually use it in brewing equipment.

Dishwasher Water Pump VP60K

Dishwasher Water Pump VP60K is a small water pump that built by a bldc motor. It is design and developed for Dishwasher machine.

VOVYO

Food Grade Pumps designed only for your Food & Beverage appliance.

Always can be found out a outstanding food safe water pump for your application in our product catalog.

Compact size, high efficiency

- Mini size of our pump body allows you to easily installed it into most your products .

- High efficiency saves you a lot of electricity cost for long term using.

FDA Material Used

- FDA Material Used Our food grade water pumps are made of PPE material which meets FDA.

- Our food grade pumps can work with as high as 100℃ temperature water for a long time.

Long life Span & Lower Noise

- Life Span:long life span more than 20,000 hours.

- Low noise:<35dB From 1M distance; Duty work:can sustain continuous 24 hours work.

Want to talk about your needs with us?

Table of Contents

Features of Food Grade Water Pump

As a kind of 12v or 24v brushless dc pump that driven by a brushless dc motor. Food grade Water pump has many advantages when compares with pump that driven by a ac motor and has following features:

- Compact design, quiet, powerful brushless dc pump motor can work for a long-term continuous operation.

- Efficient ECM brushless dc motor, long life more 20,000 hours.

- As a quiet water pump , its working noise is very low, some of them’s working noise even low to 28dB.

- Advanced magnetic drive technology, static seal, permanent No leakage.

Efficient and balanced impeller, smoother and quieter operation. - High temperature resistance of 100 degrees Celsius, food grade materials which meet FDA standard, heat resistant materials meet the needs of the food or beverage industry.

- Various forms of power supply: Food safe Water pump can be powered by DC supply, solar panel, some of them even can be used as a battery powered water pump which can be driven by dry battery and storage battery.

Applications of Food Grade Pump

Brushless centrifugal food grade pump is specially designed for common, commercial and industrial applications. It can be used for pumping pure water, sea water and other types of liquids that are compatible with water pump materials and have a viscosity similar to water. Its main applications as below:

- Conventional water transfer

- Coffee machine

- Water dispenser

- Vending machine

- Beverage machine

- Beer maker

- Medical equipment

- Other food fluid circulation machine

How to Choose a Food Grade Water Pump

There are many types of food grade water pumps in the market. So, what are the principles for customer to purchase a food grade transfer pump for their product or application? Generally speaking, Below 5 principles need to be followed.

1. Materials

As the pump is used for transfer food, beverages, drinking water that drink by customer. So, all the materials that directly contact with the fluids must be food safe material, otherwise its harmful to people’s health. Such as the material used for making pump impeller, shaft , pump body etc.

2. Pump Motor Type

You should choose a pump that driven by a brushless dc motor if you use the pump in household electrical appliances such as coffer maker, water dispenser etc. Which has high requirements on its work life span. Since the brushless motor with life span 10 times than that of Ac motor or brushed dc motor.

3. Save Cost

Calculate your requirements on the food grade water pump’s working voltage, water head and water flow etc, according to your application requirements. Then select the pump’s performance is enough competitive for your application that can save much cost than select a more powerful pump.

4. Work Condition

You must take environment temperature, working fluids into consideration for your application when choose a food grade water pump. You can’t choose a pump with max working temperature just 50 Centigrade degree for a application that requires 100 Centigrade degree working temperature.

5. Functional Requirements

You should choose a PWM, or Voltage Speed adjust way pump for your products or application if you have the needs on speed adjust.

Follow below notice when use a food safe water pump

To let the actually working life span of the food grade pump reach its design working life span, there are following notice need to be followed when use the pump:

- It is forbidden to idling(except for pump with idling protection function)

- Prohibit the reverse connection the positive and negative poles (except for special customization)

- Do not use it if there is any falling or severe vibration.

- Do not use it pump liquid that contains impurities or magnetic particles.

- Liquid temperature cannot be high than 80 ° C (except for high temperature models)

- Do not use it pump acidic or alkaline.

How to clean a food grade liquid pump?

Cleaning project

- Scrape off the scale and rust accumulated in the inner and outer surfaces of the impeller,seal ring and bearings, and then clean it with water.

- Clean the grease and rust accumulated on the joint surfaces of the casing.

- Clean the water seal tube and then check to see whether it is blocked or not.

Remove the grease, cean the bearing bush and bearings, then clean the oil ring and oil level gauge. Ball bearings should be cleaned by gasoline. - Components of the food grade water pump that are not assembled for the time being, should be oiled after cleaning.

Cleaning Principle

- For sprayed, plated, bonded workpiece surfaces, the cleaning requirements are high. Different cleaning agents and cleaning method must be used according to different requirements during cleaning to guarantee the required cleaning quality.

- Prevent corrosion of components and any degree of corrosion on precision parts is not allowed. Consider the anti-rust ability of the cleaning solution or consider other anti-rust measures, when the parts need to be parked for a period of time after cleaning.

- Ensure safe operation when clean the food safe water pump,prevent fire harm the human body and pollute the environment.