Automotive Electric Water Pump

Home > Automotive Electric Water Pump

Unique Electric water pumps in the world: 1. Max head: 45m, Max flow: 6000L/hour. 2. Max head:18m, Max flow: 16,800L/hour.

An automotive electric water pump is a 12v or 24v electric coolant pump works in your car, which delivers coolant to various components, dissipates heat from engine, EV battery and other heating parts, prevents them from overheating. It is a key component in automobile cooling system.

As a new type of automotive water pump, car electric water pump are widely used for EV, vehicles, truck, bus, motorcycle, street car, three-wheeler, fuel cell, battery cooling systems. Electric water pump is the core important function component of the new energy vehicle cooling system. Its performance and quality has a great impact on the performance of the car.

Standard Automotive Electric Water Pumps by VOVYO:

12V Electric Water Pump Auto VP80F

Max Head: 10M Max Flow: 50L/min

12v Auto Water Pump VP80E

Max Head:10~14M Max Flow:50~55L/min

Electric Water Pump Car VP90A

Max Head:24~25M Max Flow:100L/min

12v Engine Coolant Pump VP80C

Max Head: 9M Max Flow: 46L/min

Automotive Coolant Pump VP80B

Max Head: 9M Max Flow: 41L/min

Electric Water Pump for Engine VP80A

Max Head:9~12M Max Flow:41~48L/min

12v Electric Water Pump Motorcycle VP50N

Max Head: 3M Max Flow: 25L/min

Race Car Electric Water Pump VP62E

Max Head: 7~9M Max Flow: 32~35L/min

Inline Water Pump for Car VP80D

Max Head: 10~12M Max Flow: 50L/min

Auto Electric Water Pump for Bus VP90C

Head:9M Flow:120~180L/min

Electric Water Pump For Engine VP90B

Max Head:6~11M Max Flow:150~165L/min

Car Electric Water Pumps (All 20 Models)

Max Head: 5M Max Flow: 40L/min

Want to learn more?

Table of Contents

Why Choose VOVYO Automotive Electric Water Pump?

For past more than 10 years, VOVYO has won the recognition of many customers from all over the world by continuously providing innovative and high-quality automotive water-cooling electric water pump products. Our product range is wide, covering 20~500W water-cooling circulation system electric water pumps for motorcycles, racing cars, private cars, EV car, buses, engineering vehicles, aircraft, yachts, heat pumps,etc. Combining our unique patented impeller design, innovative structural design and efficient structure (including motor and electrical control design and low noise performance). We also provide OEM, ODM electric water pump customization services.

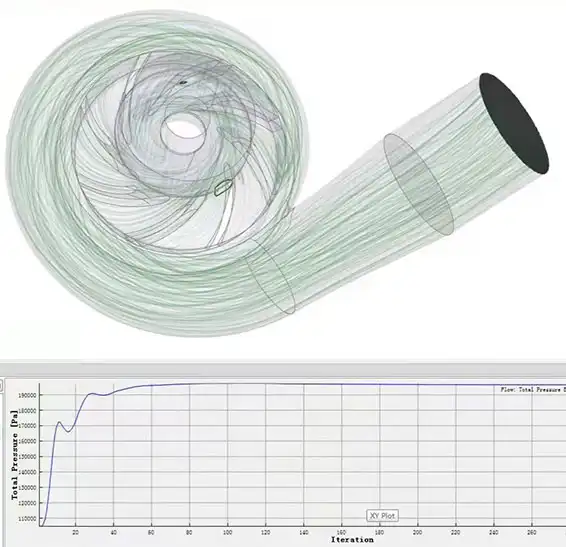

1. Product R&D

Our products are innovative everywhere, including the motor, impeller, flow channel, controller, product appearance, inlet and outlet of the water pump. Engineering expertise plus advanced motors, fluid mechanics simulation software, testing equipment, etc. give VOVYO strong design and R&D capabilities. Advanced R&D tools such as motor simulation software, Fluent fluid simulation software, high and low temperature test equipment, vibration test equipment, salt spray test equipment, etc. are used to develop high-performance, low-noise and cost-effective products. Based on the strong R&D capability VOVYO developed a lot of unique electric water pumps in the world. Such as 500W power consumption 45m max head, 100L/min max flow version VP90E pump, 500W 18m max head 280L/min water flow version VP90D pump, 120W 32m max head 26L/min max flow version VP60P pump ,etc.

2. Manufacturing

VOVYO’s production equipment is relatively advanced, with automatic and semi-automatic equipment for electric water pump assembly and advanced computerized equipment. It has developed a unique production and assembly process in the industry, and assembles and tests on automated production lines, which greatly improves the quality rate and reliability of electric water pumps, and reduces the defect rate to almost 0, providing customers with strong production capacity and high-quality, cost-effective products.

3. Quality Assurance

VOVYO is an ISO 9001 certified manufacturer of electric water pump products. It implements rigorous reliability testing at the design stage of the pump and implements statistical process control and 9001 quality control in each production process. Due to its excellent performance in quality and reliability, it has won recognition and awards from customers from all over the world.

Automotive Electric Water Pump Manufacturer

VOVYO Technology Co., Ltd is a automotive electric water pump manufacturer located in Dongguan city of China. We specialized in developing and manufacturing car electric water pumps, motorcycle electric water pump and other dc pumps. Most of our electric water pump automotive are driven by a 12v , 24v or 48V bldc motor. Widely used in various vehicles, car, new energy bus, motorcycle, race car etc. Moreover, our automotive electric water pump has many function such as PWM/CAN/LIN control, idle protection, dry-running protection, etc.

VOVYO brand automotive electric water pumps not only well sold in China market, but also exported to overseas markets such as USA, India, UK, Germany, Australia, Canada, Japan, South Africa, South Korea, Brazil, France, Spain, Italy, as well as other markets.

Automotive Electric Water Pump Working Principle

An automotive electric water pump is a dc water pump with an electronic control drive unit, it helps pressurizes and transports coolant through the high-speed rotating impeller to circulate it in your car’s engine cooling circuit, or new energy vehicle motor controller cooling circuit, battery cooling circuit to absorb and take away heat, accelerate the heat dissipation. Plays a very important role in your car’s cooling syestem. So as to ensure that the engine, battery, and motor control system work normally under the most suitable temperature state. Electric water pump is one of the most important and core functional components in your car’s cooling system.

Due to the electronic control unit included, which can control the water pump through the motor unit according to external signals. So people can adjust the working status of the pump at will, such as: control the pump to start start/stop, speed control, flow control, pressure control, and can also be set to prevent dry running protection, locked rotor protection, reverse connection protection and other protection functions. Electric water pump generally use PWM/CAN/LIN communication, it can meet various communication requirements.

Benefit of Electric Water Pump

Car water cooling pump is a mechanical device used to accelerate the circulation of automobile coolant. At current, the mechanical car water pump usually has a complicated structure, high production costs, small working water head, large flow rate, slow heat dissipation, short life, high fuel consumption. However, electric water pump can meet the thermal management technical requirements of the electronic component in drive motor controller, and battery under any working conditions of the vehicle. The main Benefit of Electric Water Pump are as follows:

1. Fast Heat Dissipation

As we all know, motors and control devices of new energy vehicle generate a lot of heat during work. It will affect the performance of the drive motor and reduce the life of the motor. Most seriously, vehicle will be self-ignite due to the short circuit. If the system can not the dissipate heat in time. Therefore, auto manufacturer use electric water pump as a hot water recirculating pump to pressurize the coolant to accelerate the dissipation of the heat.

2. Prolong Engine Working Lifespan

Electric water pump can accurately match the operating conditions of the internal combustion engine and the running state of the vehicle. Besides that, it can achieve the goal of optimizing the engine installation space. Prolongs the service life of the engine, as well as saving energy and protecting the environment.

3. Reduce Fuel Consumption and Vehicle Usage Costs

Compares with traditional mechanical water pumps, automotive electric water pumps have obvious advantages. Such as precise control of cooling effect, reduction of power loss of the engine, low fuel consumption etc.

4. New Energy Vehicles Cannot Use Mechanical Water Pumps

Mechanical water pumps that rely on engines cannot work. Since motors drive the new energy vehicles runs. However, motors still require temperature control of the cooling system. Therefore, new energy vehicles must use car electric water pumps.

5. After Parking, Electric Water Pump Can Still Work to Cool The Turbine

As we all know, traditional machine water pump will stop working, after the engine stops, and the warm air is gone. Although, some vehicles have auxiliary water pumps, these pumps still cannot be compared with automotive electric water pumps, since people still can continue to use warm air after the car stops if the car install with electric water pump car. Therefore, it has an extended parking warm air function. And the electric water pump automotive will automatically work for a period of time after the engine flameout, and continue to dissipate heat for the turbine.

6. Electric Water Pump is More Smarter than Mechanical Water Pump

Car water pump is the core component of the automobile cooling system, and its role is to pressure boost for the circulation of the coolant (antifreeze). At current, most vehicles use a mechanical water pump. However, mechanical water pump has a flaw, that is it is not smart enough to stop working automatically when work in a cold weather. In order to solve this problem, high-end car models and new energy vehicles usually use electric water pump to replace the machine water pump, the former is powered by a motor and controlled by a computer module.

In this way, the automotive electric water pump can be turned on and off according to the needs of the coolant temperature. And even the speed of the water pump can be adjusted to adjust the coolant pressure. Electric water pump for car generally driven by a brushless dc motors, therefore it does not require frequently maintenance and replacement like a mechanical water pump does.

What Types of Electric Water Pumps Are there?

Car water pump is the core component of the engine cooling system and is used to cool the automobile engine. People divide automotive water pump into mechanical water pump and electric water pump according to the driving method. We further divide electric water pump into brushless DC electric water pump and brushed DC electric water pump. According to the motor drive form of the water pump. People more commonly use the mechanical water pumps in traditional automobiles. While mainly use electric water pump in new energy vehicles and some high-end vehicles.

1. Mechanical Water Pump

Mechanical water pump is driven by the engine, and the cooling effect is proportional to the engine speed. Centrifugal water pumps are widely used in automobile engines. Its basic structure is composed of water pump casing, connecting plate or pulley, water pump shaft and bearing or shaft bearing, water pump impeller and water seal device and other parts, which are the main components of the automobile.

2. Electric Water Pump

The motor control unit of electric water pump uses current control to determine whether it needs to work according to changes in engine temperature. The mechanical water pump that relies on the engine cannot work, if a new energy vehicle is driven by a motor. However, the motor still needs the temperature control of the cooling system, so the new energy vehicle must use an car electric water pump.

Electric Water Pump VS Mechanical Water Pump

Compared with mechanical water pump, electric water pump has many advantages such as compact structure, easy installation, strong functionality, flexible control, stable performance, low noise, low power consumption, high efficiency, and good reliability. Specifically:

1. Speed Adjustable

Compared with mechanical water pump, the speed of the electric water pump is not affected by the engine speed, and can work flexibly according to the actual cooling demand of the engine. Thus, reducing heat transfer loss and mechanical loss, reducing fuel consumption, and increasing efficiency.

2. Good High and Low Temperature Resistance

Electric water pump has high temperature resistance and good corrosion resistance, since it can usually work in an environment of -40~120°C with stable performance and good reliability.

3. Easy Installation and Flexible Control

For new energy vehicles (NEV), there is no belt drive and easy installation. The water pump is directly controlled by the vehicle’s electronic control unit. The electric water pump has both the signal receiving and status feedback functions. It can feedback the running status in real time while receiving instructions, and its control is flexible, which can effectively ensure the safe driving of the car.

4. Small in Size, Low in Noise

Automotive Electric water pump has compact structure, small size, light weight, low noise during operation, stable operation and low energy consumption, which is very suitable for the high endurance and low noise needs of new energy vehicles.

5. High Efficiency, Precise Control of Liquid Temperature

Electric water pump provides timely and appropriate cooling capacity, low energy consumption, high efficiency, accurate control of coolant flow based on water temperature and other information, reduces coolant flow distance and achieves a water pump displacement reduction of about 60%.

6. Reduce Fuel Consumption

Electric water pump is driven by electricity, compared with the mechanical water pump using accessory belt drive, the friction work is reduced. NEDC (New European Driving Cycle, the European endurance test standard) cycle can reduce fuel consumption by about 2%.

7. Accelerate Warm-up the Engine and Reduce Emissions

For hybrid engines, due to frequent start and stop, a faster warm-up speed is required. Since the displacement of the electric water pump can be controlled in real time, reducing the coolant flow during cold start, it can achieve the effect of accelerating the warm-up,decreasing fuel consumption and emissions.

8. Greatly Reduce the Risk of Water Leakage

The impeller of the mechanical water pump is press-fitted on the bearing of the water pump with interference fit, while the integrated magnetic impeller of the electronic water pump is driven by the magnetic core installed in the water pump housing. So that the water cavity separation from the outside can be realized. Thus, it can remove the water seal, which reduces the risk of friction loss and water leakage.

9. Multi-function

Flexible control method such as PWM, BUS, LIN etc.

10. Multiple Working Protections

Electric water pump has multiple working protections such as over temperature, over voltage, over current, etc.

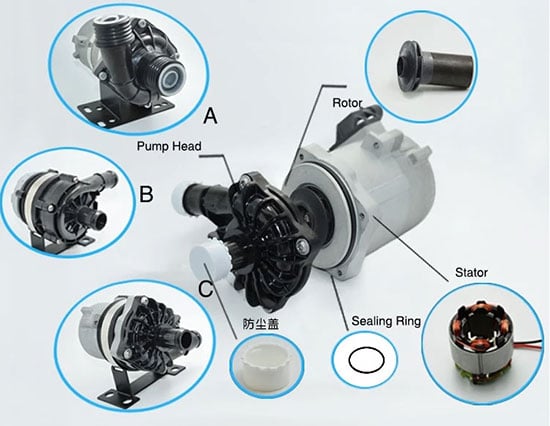

Structure of Automotive Electric Water Pump

Automotive electric water pump is mainly compose of rotor, stator, shaft,shaft sleeve, impeller, and pump body.

1. Rotor

The magnet of the BLDC pump is injection molded with the impeller and form the rotor of the motor.

2. Shaft Sleeve

There is a direct injection molding shaft sleeve in the middle of the rotor. The shaft sleeve is made by a high performance wear-resistant graphite material.

3. Stator

Pump stator and circuit board of the motor are encapsulated in the pump body with epoxy resin glue.

4. Pump Chamber

There is a chamber between the stator and the rotor. So, The rotor chamber of the motor completely isolate from the motor stator and motor control.

5. Shaft

People make the pump shaft by high wear-resistance and high-strength ceramic. It is completely sealed and leak-proof. Since the shaft connects the motor and the pump body directly. Thus it is no need to use traditional mechanical shaft seals.

6. Impeller

The vehicle electric water pump mainly uses closed impeller.

Advantages of Automotive Electric Water Pump

Automotive electric water pump is a kind of brushless dc pump. Which with advantages that mechanical pumps are incomparable.

1. Long Life

Electric water pump with life span more than 20,000 hours. Further more, it can continuously work for 24 hours per day.

2. No Leakage

There is no leakage in the electric pump due to the advanced magnetic drive and statically sealed technology used for it.

3. Wide Working Temperature Range

As a electric coolant pump, it can work in the temperature range of -40°C ~ 125°C. The engine preheating and parking heater pump can also work smoothly. Even under extremely harsh environmental conditions.

4. Polarity Protection

It can protect the pump from burning due to the wrong connection of the positive and negative electrodes.

5. Energy Saving

Energy saving: Electric water pump has the advantages of energy saving, high efficiency and environmental protection.

Selection Steps of Electric Water Pump Car

The electric water pump car selection steps are as follows:

1. Calculate the Heat Load of the Vehicle Cooling System

Calculate the heat load of the vehicle cooling system: perform the superposition calculation of the heat load of the cooled components in the cooling system to obtain the necessary maximum heat dissipation capacity, the rated heat dissipation capacity, as well as the heat dissipation change curve under some certain work conditions.

2. Simulation of the Water Resistance of Cooling System Components

Simulation of the water resistance of cooling system components: According to the reasonable requirements of the system, the relevant water resistance and flow range are formulated, and the water channels and heat sinks of the components are designed according to the flow range. Calculate the maximum flow rate at the operating point from the above maximum heat dissipation and the overall water resistance of the system.

3. Max Working Point Performance

Preliminary selection of the electric water pump car according to the flow rate and water resistance of the maximum operating point.

4. Test the Performance of Electric Water Pump at Different Speeds

According to the results of the selection of the electric water pump, perform a one-dimensional simulation analysis of the flow and water resistance under other heat dissipation to check the performance of the electric water pump at different speeds.

5. Actual Selection Process

In addition, some summary in the actual selection process is as follows:

A. The working point of the electric water pump should be in the middle of the performance curve at a certain speed.

B. The form of the automobile electric water pump is basically a centrifugal water pump, its efficiency, reliability, cost, and technology are relatively ideal.

C. The design of the cooling system needs to consider reducing the water resistance of the system as much as possible, so that the working water head of the water pump does not need to be too large, otherwise it will affect the efficiency of the water pump operation. Too high water head will increase the volume of the pump or increase the number of stages of the pump. Such a design can be avoided by system optimization.

How to Choose an Automotive Electric Water Pump ?

There are many types of automotive electric water pumps in the market. So, what are the principles for customer to purchase a car electric water pump for their application? Generally speaking, 5 principles as below need to be followed.

1. Confirm the Flow and Head

Confirm your requirements on the working voltage, head and flow of the auto electric water pump according to your application requirements.

2. Selection of Shape and Volume

People should take the volume, shape, thread interface, inlet and outlet direction of the pump into consideration. When choose a electric water pump for your application. It must be convenient for you to install the car electric water pump in your application system.

3. Confirm on Working Environment and Flow

Consider work condition factors such as environment temperature, working fluids for the pump according your application.

4. Function

Functional requirements on the electric water pump. Such as PWM speed control, FG signal, etc.

5. Purchase Cost Budget, and Supplier Survey

Correctly calculate the purchase budget cost of the electric water pump car. Inspect the pump manufacturer, require for good equipment quality, good after-sales service, supplying spare parts in time.

What special function should a Car Electric Water Pump have?

Car electric water pump usually work in a extreme working environment, which with high working temperature. This may lead to burn the pump even the car and cause huge economic losses.

For example : On November 21, 2011, BMW (China) Automobile Trading Co., Ltd. submitted a recall report to the AQSIQ. Due to the technical defects of the turbocharger car electric cooling water pump. The total number of cars involved was 3,198.

Therefore, to avoid unnecessary economic losses, customer should consider below special function. When select a car electric water pump.

- PWM Speed control function

- Idle protection function

- Stall protection function

- Reverse connection protection

- Over voltage protection function

- Fault Signal output function

- Dry-running protection

Precautions for Using an Automotive Electric Water Pump

Automotive electric water pump is a core component of cooling vehicle engine, heating air circulation system, hydrogen fuel cell heat management system, turbocharger, intake air intercooling system, new energy vehicle drive system, power battery thermal management system. As well as cooling system of vehicle, motorcycle, new energy vehicles, hybrid buses, caravan, race car, street car etc. It has its own features and strict application requirements. Otherwise, pump will be damaged or short its life span under wrong operation. Therefore, you should follow the following eight points notices when operate the Electric Water Pump Automotive:

1. Impurities Diameter

It is not allowed to use medium with impurities diameter bigger than 0.35mm or water with magnetic particles.

2. Keep Pump Chamber With Water

It is better to keep some water in the Automotive Electric Water Pump chamber before operating the pump after pump is not used for a long time.

3. Prohibit operate the Pump Without Water in Pump Chamber

It is not allowed to operate the pump without liquid for a long time.

4. Use dust cover

Use dust cover to cover the pump when unused for a long time to prevent dust entering into the inlet and outlet.

5. No Diving

Don not put the pump into liquid totally.

6. Correctly Connect Pump to the Power Supply

Confirm a correct connection before running, or malfunction may be caused.

7. Liquid Cannot Freeze at Low Temperature

Make sure that the liquid will not freeze or viscous when operate the pump in a low-temperature environment.

8. Clean the Eater Stains

Clean the water stains first before operating the pump, if water stains left at the pins of the connector.

What Causes Electric Water Pump Failure?

There are two main failure modes of electric water pump, and its reasons lead to the failures are as below::

Failure mode 1: Water temperature is abnormally high, the performance of the electric water pump is reduced, and the performance degradation may occur due to two reasons:

1. Unreliable Connection Between the Impeller and the Hollow Shaft

The impeller assembly and the hollow shaft are designed to be too small, resulting in unreliable connection between the impeller and the hollow shaft, and the impeller slips lead to its rotor speed can not reach the standard. So, the performance of the water pump will be reduced.

2. The Design of the Anti-rotation Structure of the Insert is Unreasonable

The design of the anti-rotation structure of the insert is unreasonable, causing the insert and the injection impeller to slip, resulting in the impeller speed not meeting the standard and decrease the performance of the pump.

Failure mode 2: The speed of the electric water pump is sometimes not available, it eventually drops to zero and stops working. The reasons that cause the water pump does not work are summarized as follows 5 points:

1. Unreasonable Copper Foil Thickness Design

The chip or electronic device fails, and the thickness of the copper foil does not meet the design requirements, resulting in copper foil burned when temperature rises.

2. Improper Selection of Sealing Ring Material

Improper selection of the sealing ring material of the waterproof breathable valve and aging in the extreme environment, resulting in unqualified air tightness. Then the water vapor entering the dry area, lead to short circuit of the water pump, and electric water pump stop working;

3. Design of the Welding Area Between the Reed and the Enameled Wire Is Unreasonable

The welding area design of the controller reed and enameled wire is unreasonable, and the strength of the contact segment is not enough, lead to the reed and enameled wire break , and the electric water pump cannot work.

4. Capacitors and the Bracket are Not Fixed

The capacitors at the controller or between the capacitors and the bracket are not fixed with glue, which causes the capacitors to only rely on the welding support between the pins and the reeds. Under vibration, the capacitors sway as a whole, causing the pins to fatigue and fracture due to cyclic loading. Lead to the water pump speed drops to zero.

5. Unreasonable Selection of Heat Dissipation Glue

The unreasonable choice of heat dissipation glue causes the expansion of the heat dissipation glue to produce a large number of cavities, which makes the PCB (printed circuit board) unable to dissipate heat normally, result in the over temperature failure of the electric water pump.

How to Repair an Electric Water Pump?

Electric water pump is one of the important components of the engine cooling system. It’s function is to pressurize the coolant to ensure its circulation and accelerate the heat dissipation.

However, electric water pump may malfunction during the operating period after a long-term operation. What reasons cause these faults and How to repair these faults? You can find the answer from the below table.

| Item | Fault | Reason | Solution |

| 1 | Liquid leakage | Screws are not tightened. | Tighten the screws |

| The O-ring is not installed. | Install O-ring | ||

| There are impurities on the O-ring. | Clean the O-ring | ||

| 2 | Large current, little flow | There are impurities in the rotor. | Input water in outlet to clean the rotor |

| 3 | Not working, the current is unstable (large or small) | Rotor was sucked cause by foreign matter. | Removal the foreign bodies |

| 4 | Not rotating, no current | The power line is not connected | Connect is connected properly |

| 5 | Big Noise | There is air in the pump chamber that can not discharge. | The outlet will be placed upward, ensure the liquid without air |

| There are impurities in the pump chamber. | Remove the impurities out the pump chamber | ||

| No liquid in the pump chamber, pump dry runs. | Input the liquid | ||

| Less loaded gasket | Install gasket |

Conclusion

Compared with mechanical water pump in internal combustion engine vehicles, automotive electric water pump has significant technology advantages. As the efficiency of braking energy recovery and power generation increases, electric water pump can effectively solve the power supply problems, the application of electric water pumps will become the mainstream trend.

In order to solve the problem of different temperature management requirements such as turbocharger cooling and intake air intercooling, thermal management systems based on electric water pumps have been applied, and the integrated pump-valve technical solution may be the future trend. The technology of automotive electric water pump used in new energy electric vehicles is relatively mature, and its application has become a popular trend.

PRODUCT CATEGORY

FEATURED PRODUCTS

| Rated Voltage | 24V |

| Max Head | 24Meters, 25Meters |

| Max Flow | 100L/Min, 110L/Min |

| Inlet Diameter | Φ38mm |

| Outlet Diameter | Φ38mm |

| Dimensions | 183x103x240mm |

| Noise | ~60dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 24V |

| Max Head | 45 Meters |

| Max Flow | 100L/Min |

| Inlet Diameter | Φ38mm |

| Outlet Diameter | Φ38mm |

| Dimensions | 175x100x170mm |

| Noise | ~60dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 24V |

| Max Head | 18M |

| Max Flow | 280L/Min |

| Inlet Diameter | Φ38mm |

| Outlet Diameter | Φ38mm |

| Dimensions | 188.1x100x176.9mm |

| Noise | ~60dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 13.5V, 24V |

| Max Head | 14M |

| Max Flow | 55L/Min |

| Inlet Diameter | Φ20mm |

| Outlet Diameter | Φ20mm |

| Dimensions | 131x112x80mm |

| Noise | ~48dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 220V |

| Max Head | 38M, 48M |

| Max Flow | 100L/Min,100L/Min |

| Inlet Diameter | Φ20mm |

| Outlet Diameter | Φ20mm |

| Dimensions | 223.4×126.0x178.0mm |

| Noise | ~50dB |

| Liquid Temperature | -30~70 Celsius |

| Rated Voltage | 6V, 12V |

| Max Head | 1.5 Meters, 3 Meters |

| Max Flow | 2.5L/Min, 4L/Min |

| Inlet Diameter | Φ8mm |

| Outlet Diameter | Φ8mm |

| Dimensions | 53.5x40x34mm |

| Noise | ~30dB |

| Liquid Temperature | -25~50 Celsius |

| Rated Voltage | 12V, 24V, 24V |

| Max Head | 8Meters, 13 Meters, 15 Meters |

| Max Flow | 10L/Min, 12L/Min, 13L/Min |

| Inlet Diameter | Φ18mm |

| Outlet Diameter | Φ9.8mm |

| Dimensions | 82.45×48.0x67.6mm |

| Noise | ~40dB |

| Liquid Temperature | -25~80 Celsius |

| Rated Voltage | 12V, 24V |

| Max Head | 3M, 8M |

| Max Flow | 8L/Min, 13L/Min |

| Inlet Diameter | Φ20mm |

| Outlet Diameter | Φ20mm |

| Dimensions | 82.3x102x46.4mm |

| Noise | ~40dB |

| Liquid Temperature | -40~110 Celsius |

| Rated Voltage | 12V, 24V, 24V |

| Max Head | 8Meters, 13 Meters, 15 Meters |

| Max Flow | 10L/Min, 12L/Min, 13L/Min |

| Inlet Diameter | Φ20mm (1/2 inch thread) |

| Outlet Diameter | Φ20mm (1/2 inch thread) |

| Dimensions | 83.4x48x69.7mm |

| Noise | ~40dB |

| Liquid Temperature | -25~80 Celsius |

| Rated Voltage | 12V, 24V |

| Max Head | 8M, 15M |

| Max Flow | 20L/Min, 25L/Min |

| Inlet Diameter | Φ20mm (1/2 inch thread) |

| Outlet Diameter | Φ20mm (1/2 inch thread) |

| Dimensions | 96.9x73x84.3mm |

| Noise | ~40dB |

| Liquid Temperature | -20~100 Celsius |

| Rated Voltage | 12V, 24V,24V,24V |

| Max Head | 11M, 20M, 25M, 32M |

| Max Flow | 20L/Min, 24L/Min, 25L/Min, 26L/Min |

| Inlet Diameter | Φ20.3mm |

| Outlet Diameter | Φ11.3mm |

| Dimensions | 90.9x60x85.85mm |

| Noise | ~40dB |

| Liquid Temperature | -25~80 Celsius |

FEATURES CATEGORY

SUPPORT & BLOG

Get Product Catalog

16.5Mb PDF File, Covers 200+ Models Products.