Electric motors have become an important part of our lives. They exist in electromechanical products ranging from electric vehicles to drones, robots and other electronic devices, and Mechanical and electrical products such as Brushless DC pump.

DC motors are generally divided into brushless motors and brushed motors, they have major differences in working principles, performance, etc. Below we introduce the differences, advantages and disadvantages of the above aspects:

Benefit of Electric Water Pump

1. Working Principle of Brushed Motor

Brushed motor is the first type of motor that everyone comes into contact with. Brushed motor is always shown as a model to introduce the motor in the physics class in middle school .

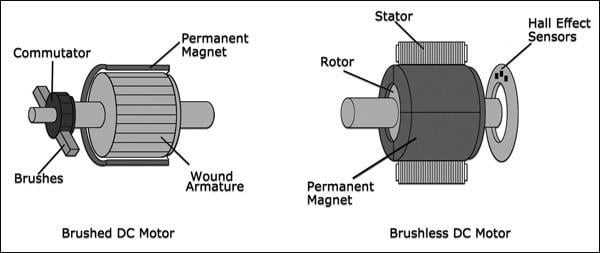

The main structure of a brushed motor is consist by stator + rotor + brushes, which obtain rotational torque through the rotating magnetic field, thereby outputting kinetic energy. The brush and the commutator are in constant contact and friction, and play a role of conduction and commutation during rotation.

The brush motor uses mechanical commutation, the magnetic pole does not move, and the coil rotates. The coil and commutator rotate, when the motor is working, but the magnetic steel and carbon brush do not rotate. The alternating change of coil current direction is realized by inverter and the brush that rotate with the motor.

2. Working Principle of Brushless Motor

In brushless motors, the work of commutation is completed by the control circuit in the controller (usually Hall sensor + controller, more advanced technology is magnetic encoder).

The brushless motor adopts electronic commutation, the coil does not move, and the magnetic pole rotates. The brushless motor uses a set of electronic equipment to sense the position of the magnetic pole of the permanent magnet through the Hall element. According to this perception, the electronic circuit is used to switch the direction of the current in the coil in time to ensure that the magnetic force in the correct direction is generated to drive the motor . The disadvantages of brushed motors are eliminated.

These circuits are motor controllers. The controller of the brushless motor can also realize some functions that cannot be realized by the brushed motor, such as adjusting the power switching angle, braking the motor, making the motor reverse, locking the motor, and using the brake signal to stop the power supply to the motor. The electronic alarm lock of the battery car now makes full use of these functions.

The brushless DC motor is composed of a motor body and a driver, and is a typical mechatronic product. Because the brushless DC motor runs in a self-control mode, it will not add a start winding to the rotor like a synchronous motor started under heavy load under variable frequency speed regulation, nor will it cause oscillation and loss of step when the load changes suddenly.

Benefit of Electric Water Pump

1. Bushed DC motor has fast response speed and large starting torque

The DC brushed motor has a fast starting response speed, large starting torque, stable speed change, almost no vibration from zero to maximum speed, and can drive a greater load when starting. The brushless motor has a large starting resistance (inductive reactance), so the power factor is small, the starting torque is relatively small, there is a buzzing sound when starting, and accompanied by strong vibration, the load is small when starting.

2. Brushed DC motor runs smoothly, with good starting and braking effects.

Brushed dc motor is speed-regulated by voltage regulation, so the starting and braking are smooth, and it is also stable when running at a constant speed. Brushless motors are usually controlled by digital frequency conversion. First, AC becomes DC, then DC becomes AC, and the speed is controlled by frequency change. Therefore, the brushless DC motor runs unevenly and vibrates when starting and braking and . It will be stable only when the speed is constant.

3. High control precision of DC brushed motor

Brushed DC motors are usually used together with gearboxes and encoders to make the output power and control accuracy of the motor more higher. Its control accuracy can reach 0.01 mm, and the moving parts can be stopped almost wherever you want. All precision machine tools adopt DC motors to control precision. Because the brushless dc motor is not stable when starting and braking, the moving parts will stop at a different position each time, and the positioning pin or stopper must be used to stop at the desired position.

4. The DC brush motor has low cost and easy maintenance.

Because of its simple structure, low production cost, many manufacturers and mature technology, DC brushed motors are widely used, such as factories, processing machine tools, precision instruments, etc. If the motor fails, just replace the carbon brushes. Carbon brushes only cost a few yuan, which is very cheap. The brushless dc motor technology is immature, the price is high, and the application range is limited. It is mainly used in constant speed equipment, such as inverter air conditioners and refrigerators. The brushless dc motor should be replaced if it is damaged.

5. Low interference of brushless dc motor

The brushless dc motor removes the brush, and the most direct change is that there is no electric spark generated when the brush motor is running, which greatly reduces the interference of the electric spark to the remote control radio equipment.

6. Low noise and smooth operation

Because of brushless dc motor with no brush, the friction is greatly reduced during operation, the operation is smooth, and the noise is much lower. This advantage is a huge support for the stability of the model.

7. Long life and low maintenance cost

Without the brush, the wear of the brushless dc motor is mainly on the bearing. From the mechanical point of view, the brushless motor is almost a maintenance-free motor. When necessary, only need to do some dust removal maintenance.