Energy Storage Cooling Pump

Home > Energy Storage Cooling Pump

Unique Energy Storage Cooling Pumps in the world: Max head: 45m, Max flow: 6000L/hour.

Energy storage cooling pump is a 12v, 24V, 48V DC electric coolant circulation pump, or a 220V AC water pump. Its built by a brushless dc motor, mainly completes two functions of coolant circulating and fluid refilling in the energy storage system. It pumps the liquid accurately through the energy storage unit and delivers the liquid to the refrigeration and heating equipment to ensure that the temperature of the energy storage system is controlled at the normal working temperature. It is a key component in energy storage cooling system.

Energy storage cooling pump’s main function is to cooling the battery pack, stabilizing the inverter temperature, optimizing energy storage performance. It is one of the indispensable core functional components in the energy storage thermal management cooling system.

Standard Energy Storage Cooling Pumps by VOVYO:

Energy Storage Cooling Pump VP80E

Max Head:14M Max Flow:50~58L/min

Energy Storage Coolant Pump VP90A

Max Head:22~45M Max Flow:100L/min

Energy Storage Water Pump VP90C

Head:9M Flow:120~180L/min

DC Energy Storage Pump VP60A

Max Head:13~32M Max Flow:11~25L/min

Energy Storage Coolant Pump VP60P

Head: 8~32M Flow: 20~26L/min Noise≤ 45dB

Energy Storage Fluid Refill Pump

Max Head: 8~15M Flow: 10~13L/min

Want to learn more?

Table of Contents

What is an Energy Storage System?

Electricity is an important driving force for the development of modern society. All walks of life and residents’ lives in today’s society cannot do without electricity supply. With the rapid development of the global economy, the demand for electricity is increasing, and the peak-to-valley difference in electricity consumption is becoming more and more serious. Therefore, the development of energy storage is of great significance. Energy storage is a key supporting technology for the energy revolution. The energy storage system can not only solve the peak-to-valley difference in electricity consumption, save resources, and reduce electricity costs, but also solve the problem of large fluctuations when new energy power generation is connected to the grid. It can also provide power supply independently in special circumstances such as power outages in the main grid to ensure power supply safety.

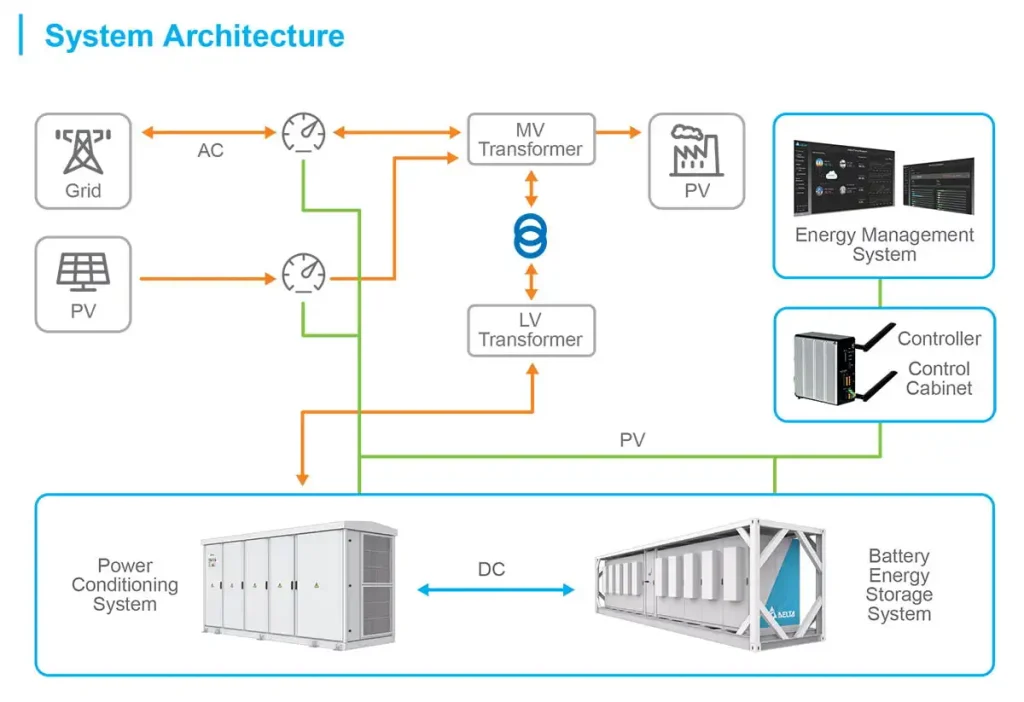

Composition of Energy Storage System

The energy storage thermal management system is mainly composed of three-in-one, compressor, condenser, expansion valve, plate exchanger, cooling fan, water pump, high and low voltage wiring harness, refrigerant pipeline, water pipe and coolant. The three-in-one includes three parts: inverter drive board, AC/DC and relay board, with protection level IP66. The coolant is generally composed of water and ethylene glycol with a volume ratio of 50% each. The thermal management unit dissipates heat or heats the energy storage battery through the coolant according to the BMS command and the collected temperature and pressure sensor data and the set control strategy.

The coolant circuit is composed of the battery pack pipeline, water pump, expansion tank, etc., and the refrigerant circuit is composed of the compressor, condenser, expansion valve, plate exchanger and cooling fan, etc. The heat of the coolant circuit and the refrigerant circuit is exchanged in the plate exchanger. During cooling, the compressor is running, and the refrigerant enters the compressor through the condenser, expansion valve, and plate exchanger to complete a cycle. The heat of the coolant that dissipates heat for the battery is taken out in the plate exchanger, and the heat of the refrigerant is dissipated in the condenser through the cooling fan.

Working Principle of Energy Storage Cooling Pump

The energy storage water cooling pump is usually a 24V 48V low-voltage electric water pump, or a 220V AC pump, which pushes the coolant through the pipe system. The water pump circulation function is mainly divided into: liquid circulation, circulation cooling, circulation heating, pressurized delivery and other characteristics. It accurately flows the liquid through the energy storage unit and guides the liquid to the refrigeration and heating equipment to ensure that the energy storage temperature is controlled at normal working temperature. The efficient operation and flow adjustability of the water pump have a greater improvement in energy utilization for energy storage equipment of different capacities. The circulation water pump needs to be determined according to the scale, design parameters and load heat generation of the energy storage system. In general, larger capacity energy storage requires higher flow and head to ensure the temperature balance inside the energy storage.

Function of Energy Storage Coolant Pump

Energy storage cooling pump is a brushless dc pump, it is an important component in the liquid-cooled industrial and commercial energy storage system, and undertakes two key functions: circulation and fluid refill.

In terms of circulation function, the water cooling pump guides the coolant from the energy storage unit to the cooling equipment through the characteristics of high efficiency, adjustable flow and pressure output, reduces the system temperature and maintains the normal working temperature of the energy storage device. The high efficiency and adjustability of the water pump enable it to adapt to different load requirements and improve energy utilization efficiency.

In terms of fluid refilling function, the water pump plays a key role in automatic fluid refilling. During the operation of the system, the coolant may be reduced due to evaporation or leakage. At this time, the water pump will automatically start according to the liquid level signal monitored by the system to add an appropriate amount of coolant to maintain the cooling effect and safety of the system.

The Main Uses of Energy Storage Cooling Pumps

The main uses of energy storage cooling pumps include cooling battery packs, stabilizing inverter temperature, optimizing performance, etc. In fact, it is an indispensable core functional component of energy storage thermal management systems. Below VOVYO explains the above three uses in detail:

1. Cooling the battery pack

Energy storage systems, especially those using lithium-ion batteries, generate a lot of heat during the charging and discharging process. The cold pump can circulate the coolant through the battery pack to help dissipate the heat, thereby preventing the battery from overheating and improving battery efficiency.

2. Stabilizing the inverter temperature

The inverter is a key device for converting electrical energy in the energy storage system. By using a water cooling pump to maintain it within a full and effective temperature range, the inverter can be guaranteed to operate efficiently and stably.

3. Optimizing energy storage performance

Through an effective cooling system, the water cooling pump helps the energy storage system operate at the optimal temperature, avoids the impact of temperature waves on system performance, and improves overall energy output and storage efficiency.

The Impact of Cooling Pump on the Performance of Energy Storage System

As a dc water pump, energy storage water cooling pump has many effects on the energy storage system, including: improving the performance of the energy storage system, extending the life of each device unit in the system, enhancing the safety of the entire system, etc. Here, VOVYO will explain its effects in detail below for you.

1. Improve energy efficiency

Effective cooling can significantly improve the energy efficiency ratio of energy storage systems, because the equipment is most efficient when it runs at an appropriate temperature.

1. Cooling the battery pack

Through an effective cooling system, the water cooling pump helps the energy storage system operate at the optimal temperature, avoids the impact of temperature waves on system performance, and improves overall energy output and storage efficiency.

2. Extend equipment life

Overheating is one of the main causes of battery and electronic equipment failure. Water cooling pumps can reduce thermal stress and extend the service life of equipment by keeping the equipment running at an optimal temperature.

3. Enhance system safety

Overheating of energy storage systems may lead to safety issues such as battery thermal runaway. Water cooling pumps reduce this risk through effective cooling management and ensure the safe operation of the system.

Water cooling pumps (liquid cooling pumps) play an indispensable role in the energy storage industry. They not only help optimize system performance, improve energy efficiency and safety, but are also one of the key technologies to ensure the stable operation of energy storage systems. With the continuous advancement of energy storage technology and the expansion of the market, the design and technology of water cooling pumps (liquid cooling pumps) will continue to evolve to meet the needs of higher efficiency and higher safety standards. As home energy storage enters a rapid development stage, liquid-cooled energy storage systems are also gaining more and more attention.

How to Choose an Energy Storage Cooling Pump

At present, there are many types of energy storage water pumps on the market, with different performances, models and qualities. How to choose a cooling water pump that is more suitable for your energy storage system? You may not know much about water pumps and don’t know how to choose the most suitable and competent water pump to meet the needs of your energy storage system. The following are some experiences on how to choose energy storage cooling water pumps for your reference.

1. Choose a pump with stable performance

A water pump with stable performance can make the energy storage liquid cooling system run normally for a long time. There are many factors that determine the stability of the water pump performance. The most important one is the performance of the internal electronic components. VOVYO has very strict control requirements for the supply chain. The incoming materials are 100% screened and tested. Only after they fully meet the inspection standards can they enter the next link. In addition, the innovative and unique production and manufacturing process has improved the stability and reliability of the products compared with peer manufacturers.

2. Choose a long working lifespan pump

Long life means no frequent replacement, reducing the maintenance cost of energy storage users. The energy storage water pumps produced by VOVYO are all constructed by brushless DC motors, with a design life of 50,000~60,000 hours and a service life of more than 30,000 hours, which is much higher than the industry standard and is particularly suitable for the energy storage industry’s demand for high reliability and long life of water pumps.

3. choose automotive-grade energy storage electric water pumps

VOVYO’s VP90E and VP90D energy storage electric water pumps can be used in a variety of extremely harsh environments, such as ambient temperature: -40 ~ 125℃, medium temperature: -40 ~ 120℃, etc. The reliability, durability, efficiency and stability in extreme environments are much higher than conventional energy storage water pumps.

3. Choose an electronic water pump with CAN function

CAN function communication can better meet the needs of energy storage customers for pump control accuracy and operation monitoring, precise control, and precise operation monitoring

PRODUCT CATEGORY

FEATURED PRODUCTS

| Rated Voltage | 24V |

| Max Head | 24Meters, 25Meters |

| Max Flow | 100L/Min, 110L/Min |

| Inlet Diameter | Φ38mm |

| Outlet Diameter | Φ38mm |

| Dimensions | 183x103x240mm |

| Noise | ~60dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 24V |

| Max Head | 45 Meters |

| Max Flow | 100L/Min |

| Inlet Diameter | Φ38mm |

| Outlet Diameter | Φ38mm |

| Dimensions | 175x100x170mm |

| Noise | ~60dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 24V |

| Max Head | 18M |

| Max Flow | 280L/Min |

| Inlet Diameter | Φ38mm |

| Outlet Diameter | Φ38mm |

| Dimensions | 188.1x100x176.9mm |

| Noise | ~60dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 13.5V, 24V |

| Max Head | 14M |

| Max Flow | 55L/Min |

| Inlet Diameter | Φ20mm |

| Outlet Diameter | Φ20mm |

| Dimensions | 131x112x80mm |

| Noise | ~48dB |

| Liquid Temperature | -40~125 Celsius |

| Rated Voltage | 220V |

| Max Head | 38M, 48M |

| Max Flow | 100L/Min,100L/Min |

| Inlet Diameter | Φ20mm |

| Outlet Diameter | Φ20mm |

| Dimensions | 223.4×126.0x178.0mm |

| Noise | ~50dB |

| Liquid Temperature | -30~70 Celsius |

| Rated Voltage | 6V, 12V |

| Max Head | 1.5 Meters, 3 Meters |

| Max Flow | 2.5L/Min, 4L/Min |

| Inlet Diameter | Φ8mm |

| Outlet Diameter | Φ8mm |

| Dimensions | 53.5x40x34mm |

| Noise | ~30dB |

| Liquid Temperature | -25~50 Celsius |

| Rated Voltage | 12V, 24V, 24V |

| Max Head | 8Meters, 13 Meters, 15 Meters |

| Max Flow | 10L/Min, 12L/Min, 13L/Min |

| Inlet Diameter | Φ18mm |

| Outlet Diameter | Φ9.8mm |

| Dimensions | 82.45×48.0x67.6mm |

| Noise | ~40dB |

| Liquid Temperature | -25~80 Celsius |

| Rated Voltage | 12V, 24V |

| Max Head | 3M, 8M |

| Max Flow | 8L/Min, 13L/Min |

| Inlet Diameter | Φ20mm |

| Outlet Diameter | Φ20mm |

| Dimensions | 82.3x102x46.4mm |

| Noise | ~40dB |

| Liquid Temperature | -40~110 Celsius |

| Rated Voltage | 12V, 24V, 24V |

| Max Head | 8Meters, 13 Meters, 15 Meters |

| Max Flow | 10L/Min, 12L/Min, 13L/Min |

| Inlet Diameter | Φ20mm (1/2 inch thread) |

| Outlet Diameter | Φ20mm (1/2 inch thread) |

| Dimensions | 83.4x48x69.7mm |

| Noise | ~40dB |

| Liquid Temperature | -25~80 Celsius |

| Rated Voltage | 12V, 24V |

| Max Head | 8M, 15M |

| Max Flow | 20L/Min, 25L/Min |

| Inlet Diameter | Φ20mm (1/2 inch thread) |

| Outlet Diameter | Φ20mm (1/2 inch thread) |

| Dimensions | 96.9x73x84.3mm |

| Noise | ~40dB |

| Liquid Temperature | -20~100 Celsius |

| Rated Voltage | 12V, 24V,24V,24V |

| Max Head | 11M, 20M, 25M, 32M |

| Max Flow | 20L/Min, 24L/Min, 25L/Min, 26L/Min |

| Inlet Diameter | Φ20.3mm |

| Outlet Diameter | Φ11.3mm |

| Dimensions | 90.9x60x85.85mm |

| Noise | ~40dB |

| Liquid Temperature | -25~80 Celsius |

FEATURES CATEGORY

SUPPORT & BLOG

Get Product Catalog

16.5Mb PDF File, Covers 200+ Models Products.